something old, something new, …

From traditional stonemasonry to advanced CNC machinery work

Let us introduce you to an old lady, Jenny Lind.

No, this is not the story of the “Swedish nightingale”, the famous opera singer of the XIX century who, allegedly, conquered the heart of P.T. Barnum.

Our Jenny Lind is the oldest machine at stoneCIRCLE, which we still use today for manual slab polishing.

The Jenny Lind is a radial arm manual machine, which needs a skilled mason to operate it. Despite its age we still use it regularly for polishing or honing small cut-to-size pieces.

When it comes to bigger slabs and more complex jobs, we work with second-generation machines, like the Denver Vision X. This automated machine, once set, can polish, hone, brush and apply a few other finishes to the slab by itself. This allows the masons to work on other projects whilst the machine operates.

Technological advancement never stops! So the designers’ creativity.

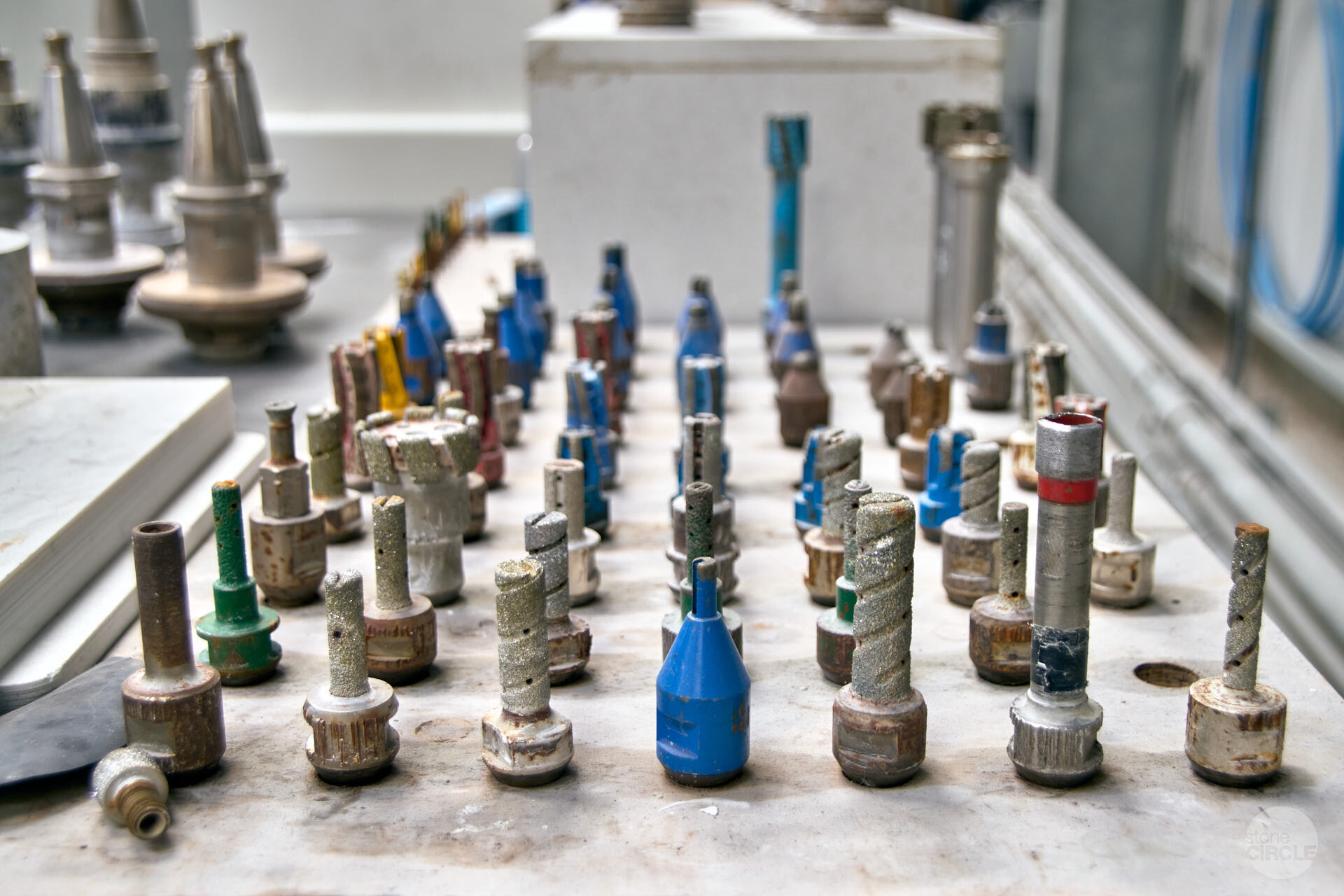

For other advanced work, we prepare a 3D model on the computer, which then talks directly with our five-axis OMAG machine. This uses saw blades, drills and diamond-coated routers to mill and shape a block of stone in all directions. For some pieces we program the machine to work unattended all night which speeds up the delivery time.

See this work in progress, Course and Flow, an artwork by Rachael Champion on the Omag 5-axis CNC…

3D graphics courtesy of OMAG SpA

Here are some examples of works we have produced on our Computer Numerical Control (CNC) machines.

Although our state-of-the-art technology and CNC machinery can fulfil any advanced design requirement, we never forget the importance of traditional stonemasonry skills. The machines free up the masons to finish the pieces by hand.

Thanks to our investments in stone processing technology and our team of skilled masons no job is too big or too small for us.